The mill is the core equipment of the whole flour mill, and the grinding roller is the central part of the mill. The quality of grinding roller drawing and grinding and blasting directly affects the overall output, tonnage electricity consumption, flour sensory quality and internal quality, grinding machine precision, service life, flow balance, mass balance, etc. Therefore, we must pay attention to the quality of grinding roller drawing and grinding and blasting to ensure the production process requirements.

-- From Grain and Fats

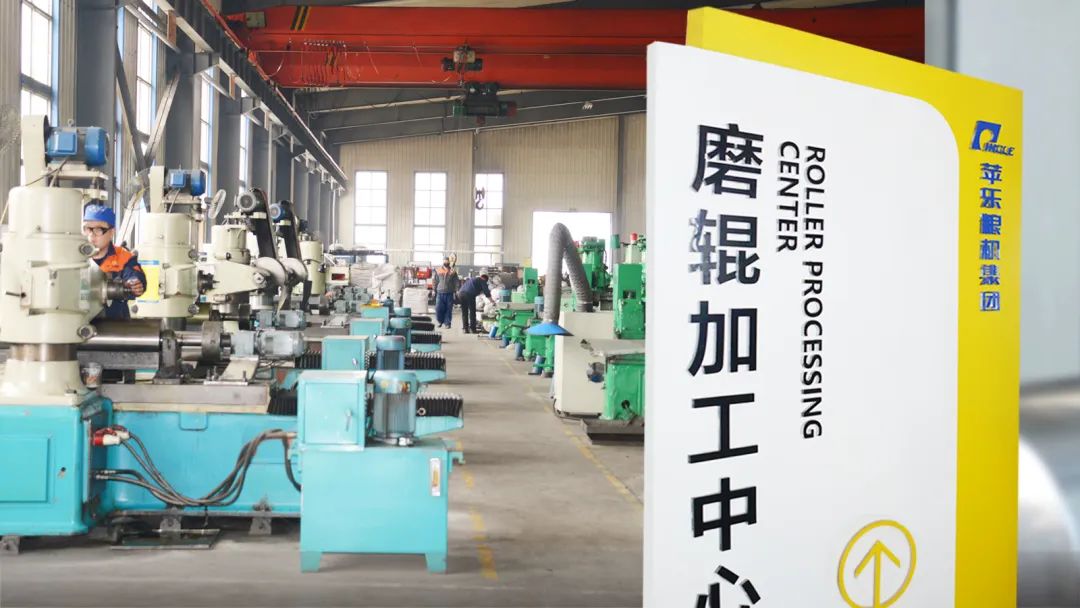

After reading the above article, I think we all have an understanding of the importance of grinding roller processing, below, I will take you to the Appleseed Grinding Roller Processing Center to introduce you in detail how the quality grinding roller is processed, follow me!

In the process of flour production, the grinding process of the mill is one of the most important production processes, especially the technical characteristics of the grinding roller surface, which is one of the most important influencing factors. For many years, Pingle has been adhering to the service concept of "customer-oriented" and has attached great importance to the improvement of the grinding quality of the mill.

Since its establishment, Pingle Grinding Roll Processing Center has been focusing on the advantages of equipment, personnel and technology, constantly upgrading and optimizing management, and has now formed a comprehensive service capability of grinding roll processing, including grinding roll inspection, polishing, medium convexity measurement, wire drawing, sand blasting and dynamic balance correction. The grinding roller processing center of Apple has more than ten sets of special equipment such as hydraulic grinding machine, medium convexity measuring instrument, high-speed wire drawing machine, dynamic balancing machine, sand blasting machine, etc. We have also purchased high-grade CNC wire drawing machine and equipped with experienced wire drawing workers to operate it, so that we can realize large-scale operation and provide customers with high-quality grinding roller processing services.

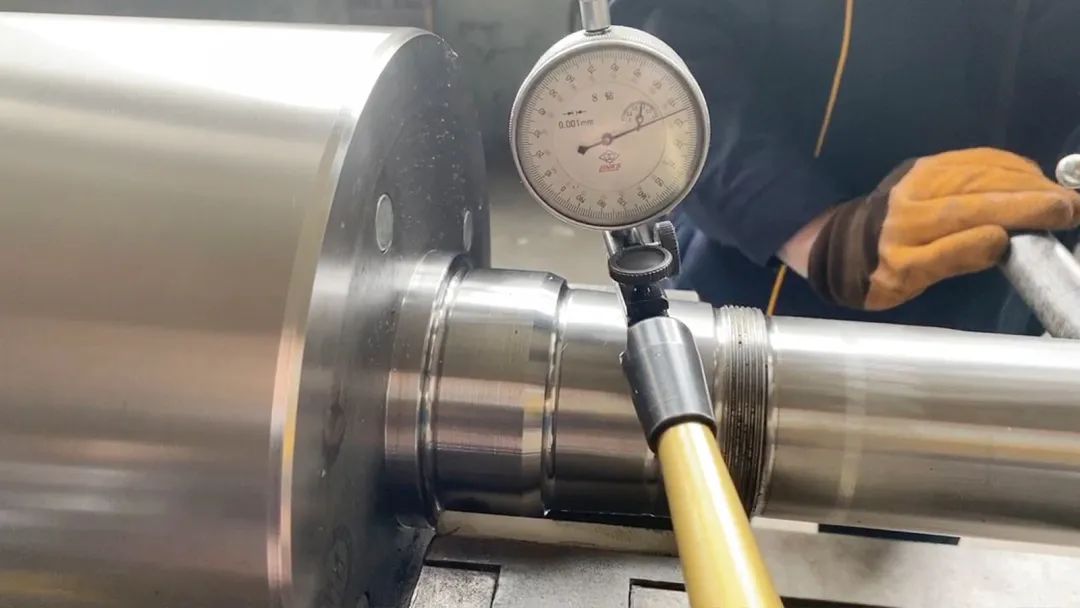

Before entering the grinding roller processing process, each grinding roller in Appleseed is inspected in detail with professional inspection tools for its key dimensions, including roll body hardness, shaft hardness, end face hardness, form tolerance, roughness, etc. Under the strict inspection of the quality inspection personnel, only the grinding rolls that meet the standard can enter the next process. Grinding roller inspection is an important link to ensure the quality of grinding roller processing.

Everyone understands it now, right? The inspection before grinding roller processing can provide an important basis for grinding roller processing. If your grinding rolls need to be processed, you can rest assured that we have a complete set of inspection methods to provide you with the most accurate data!

After the qualified grinding rolls are inspected, they will enter the process of grinding, brushing, sandblasting and dynamic balance correction, let's take a look together!

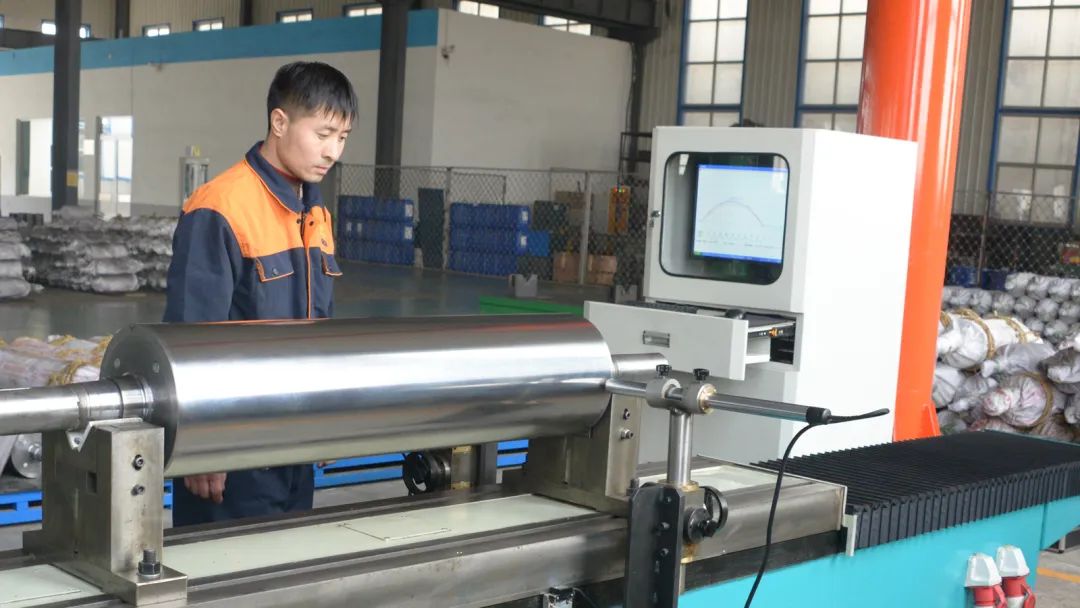

In the process of grinding roller polishing, Pingle grinding roller processing center adopts special grinding machine with fixed value of medium convexity for processing, which is specially made for special vehicles; after grinding roller polishing, it is tested by CNC high-precision medium convexity measuring instrument, and the value is collected more accurately to ensure the processing quality of grinding roller.

After grinding, the grinding rolls are brushed or sandblasted according to the customer's demand. Appleseed Grinding Roll Processing Center has more than ten sets of high-speed drawing machines and CNC drawing machines, as well as several experienced drawing workers, with advanced equipment and excellent technology, which can process various specifications of grinding rolls in the range of 350-1250mm in length and 220-400mm in diameter.

The CNC wire drawing machines are controlled by three-axis CNC system with independent programming, using precision grinding rack drive and linear rolling guide, with high drawing quality and fast speed, which can greatly meet the needs of customers.

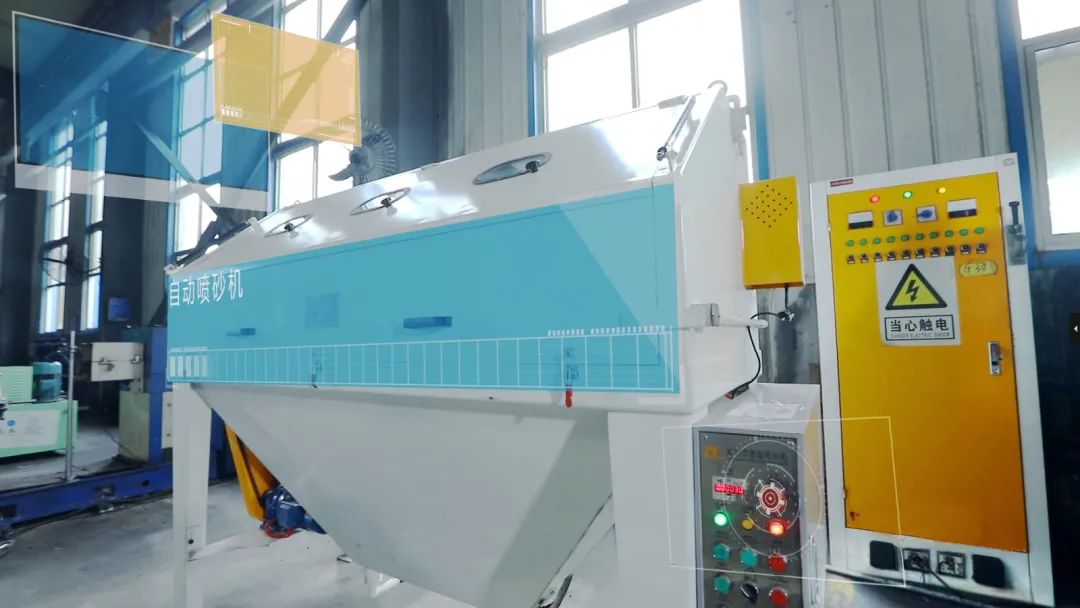

The grinding rolls required by customers to be sandblasted are first action balanced and corrected after grinding, and then transferred to the sandblasting process. There are 3 sets of professional automatic sandblasting machines in Pingle's grinding roller processing center, which can sandblast grinding rolls according to customers' requirements.

In the sandblasting process, high quality diamond sand is blown by high pressure to form a uniform sandblasted grinding surface on the surface of the grinding roller according to the set requirements, which effectively ensures the fine grinding of the grinding roller at work.

After drawing, each grinding roller has to be corrected by dynamic balancing to reduce the impact of vibration on the grinding due to high speed operation when the roller is in use and to ensure the final grinding quality.

Well, after several processes, the processing of grinding rollers is finished. The finished rolls will be sent to the customer's grinding plant from the grinding roll processing center of Applinger, creating value for the customer with high speed efficiency!

Pingle Grinding Roll Processing Center is always committed to providing customers with high quality grinding roll processing services, and has served large powder mill customers such as Wudeli, Jinshahe, Yihai Kerry, etc., and has been widely praised by customers.

This is the end of today's explanation! If you have the need of grinding roll processing, welcome to call me, we will be happy to serve you!

Appleseed Grinding Roll Processing Center

Tel: +86 13472153313

Contact: Manager Zhai

Derechos de autor © Hebei Pingle Flour Machinery Group Co., Ltd. All Rights Reserved | Mapa del sitio | Technical Support: